A product design specification template is your project’s most critical defense against the chaos, scope creep, and budget overruns that sink promising ideas. A staggering 78% of product teams cite a well-structured design specification as critical for improving alignment and stopping scope creep. This isn’t just another document; it’s the single source of truth that guarantees your engineering, design, and business teams are all building the same product. It translates an ambitious vision into a concrete, actionable blueprint, preventing the costly rework that plagues so many projects.

Why a PDS Template is Non-Negotiable for Success

Think of a Product Design Specification (PDS) as your project’s constitution. Without it, teams operate on assumptions, leading to mismatched features, blown timelines, and a soul-crushing cycle of revisions. This is the classic recipe for failure—disparate departments end up with fundamentally different visions of what the product is even supposed to achieve.

A robust product design specification template forces specificity from day one. It compels stakeholders to debate, define, and agree upon the critical details before a single line of code is written or a prototype is commissioned.

Aligning Teams and Setting Crystal-Clear Expectations

A PDS creates a shared language that everyone—from engineers to marketers—can understand and execute against. I once consulted for a consumer electronics company struggling with constant, last-minute design changes. Their hardware engineers and marketing team were in a state of perpetual conflict. Engineering focused on technical feasibility, while marketing pushed for flashy features based on loose market trends. The result? A product stuck in an expensive rework loop.

Implementing a standardized PDS template transformed their workflow. It established a formal, non-negotiable process for decision-making.

- Marketing was now required to define user personas and quantifiable market needs upfront.

- Engineering had to commit to material limitations and performance benchmarks from the start.

- Design had to anchor their mockups directly to the agreed-upon written requirements.

This single document became the definitive source of truth, eliminating ambiguity and aligning all teams toward a common goal. This isn’t just an anecdotal success story; the data is compelling.

Companies that consistently use detailed design specification templates can reduce product defects by up to 30% and achieve a 25% faster time-to-market compared to those who don’t. You can explore the structure of a PDS template to see how these benefits are realized.

This structured approach shifts your entire project from a reactive, chaotic scramble to a proactive, strategic execution. It clearly defines success by detailing everything from the product’s core purpose to its user interface and testing criteria, setting the stage for a smooth launch from the very beginning.

Building Your PDS Template From the Ground Up

An effective product design specification template is more than a sterile checklist. It’s the narrative of your product, guiding it from a raw concept to a market-ready solution. It helps your team understand not just what they are building, but why they are building it. When executed correctly, the PDS transitions from a bureaucratic formality into a powerful strategic asset.

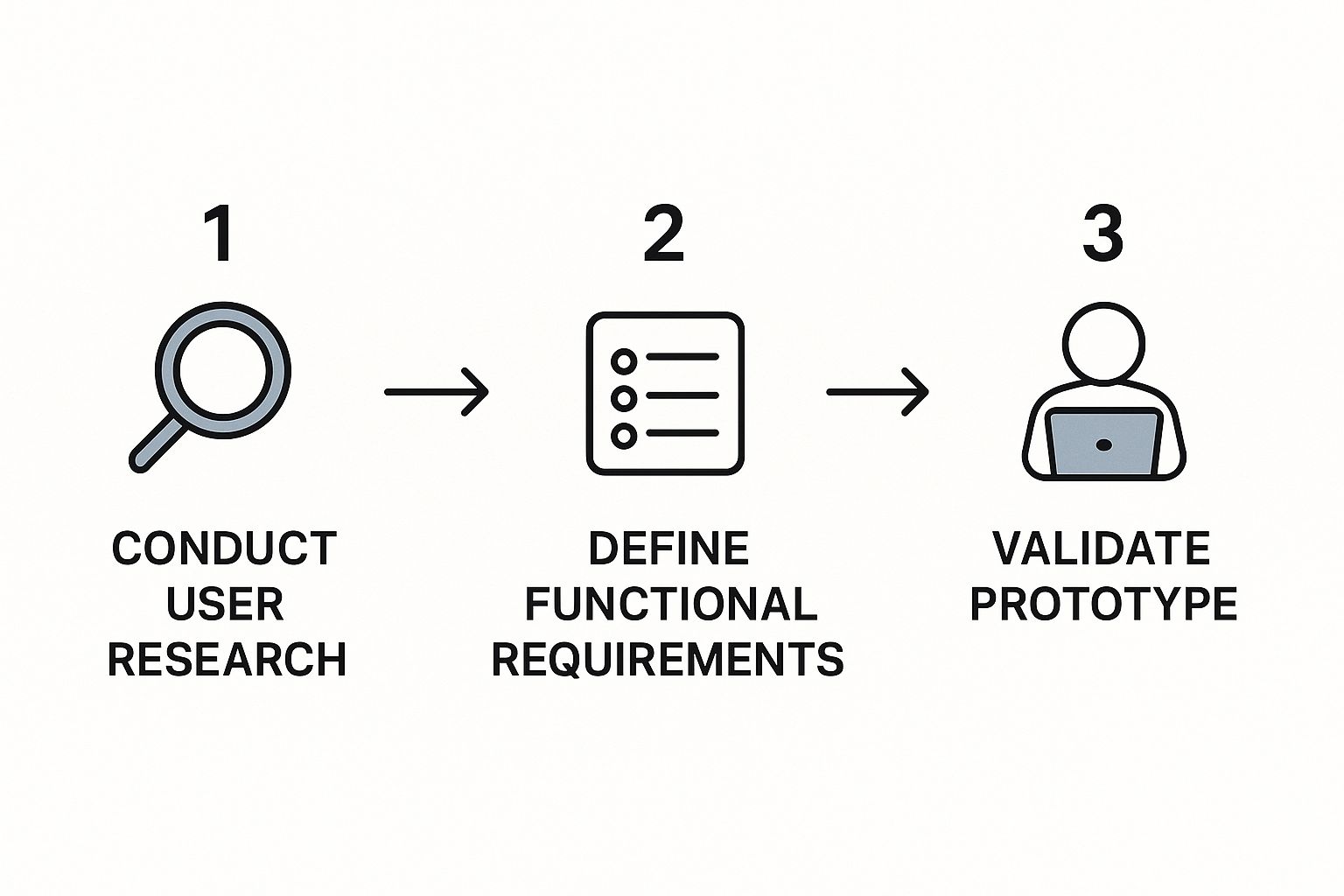

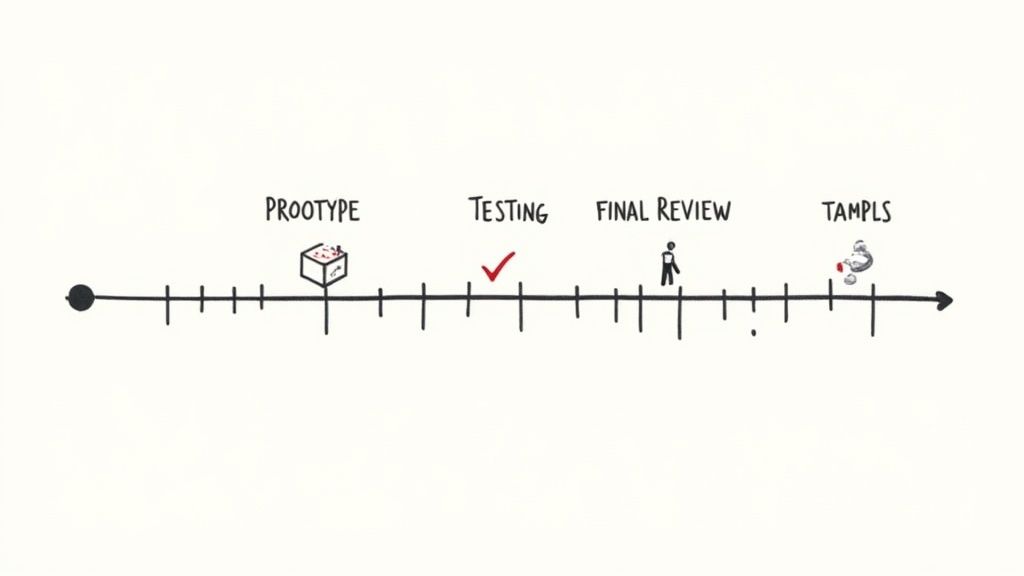

The best PDS templates are founded on a logical, repeatable process for gathering, defining, and validating requirements.

As this illustrates, robust requirements aren’t invented; they are discovered. They emerge from a deep understanding of user needs, are validated through rigorous testing, and are refined via a continuous feedback loop that drives genuine product improvement.

Core Components of a PDS

Every PDS template must be built on a solid foundation of essential components that apply to virtually any project.

An executive summary is your opening. It provides stakeholders with a concise, high-level overview of the product’s purpose, its core value proposition, and how it aligns with broader business objectives. This section sets the stage and provides immediate context for the detailed specifications that follow.

Next are your user personas. Go beyond superficial demographics. Instead of “a busy professional,” bring your user to life: “Meet Alex, a project manager overwhelmed by clunky mobile apps, who needs a streamlined way to track team progress on the go.” Providing your engineers with a clear picture of Alex’s pain points offers invaluable context for their technical decisions.

Then comes the heart of the document: the functional requirements and technical specifications. These sections form the technical core of your PDS, detailing precisely what the product must do and how it will be constructed.

I’ve seen teams falter by only listing surface-level features. A truly effective PDS goes deeper, specifying everything from material durability and power consumption to data security protocols and API response times. It is this level of detail that prevents costly rework later in the development cycle.

To help structure your document, this table distinguishes between foundational components and the advanced sections needed for more complex projects.

Essential vs. Advanced PDS Template Components

| Component Category | Essential for All Projects | Recommended for Complex/Regulated Projects |

|---|---|---|

| Project Overview | Executive Summary, Business Goals, Target Audience | Market Analysis, Competitive Landscape, Legal & Compliance |

| User Focus | User Personas, User Stories, Core Use Cases | Detailed User Journey Maps, Usability Testing Plans |

| Functional Specs | Key Features, Functional Requirements | Non-Functional Requirements (e.g., performance, scalability) |

| Technical Specs | High-Level Architecture, Tech Stack Overview | Detailed System Design, Data Schemas, API Endpoints |

| Validation & Tracking | Acceptance Criteria, Version Control Log | QA Test Cases, Risk Assessment, Maintenance Plan |

While a simple project may only require the “Essential” components, a medical device or enterprise SaaS platform would absolutely demand the “Recommended” details to mitigate risk and ensure success.

Advanced and Technical Considerations

Modern products are rarely just hardware or software; they are integrated systems. Your PDS must reflect this reality. I’ve found it’s critical to document physical attributes alongside system requirements. A comprehensive documentation suite might include a Product Requirements Document (PRD) for user-facing features, a System Design Document (SDD) for architecture, and an Interface Control Document (ICD) for APIs. You can discover more about how these technical documents work together to create a holistic product view.

Be sure to include these two crucial elements:

- Acceptance Criteria: For each requirement, clearly define what “done” means. What specific, measurable outcomes will prove the requirement has been met? Your QA team will depend on this clarity.

- Version Control: A simple change log detailing dates, authors, and a summary of updates is non-negotiable. This practice ensures everyone is working from the latest version.

By building your product design specification template with these components, you are crafting a reliable guide that empowers your team to build the right product, the right way, the first time.

How to Customize Your PDS for Different Industries

Let’s be direct: a generic, one-size-fits-all product design specification template is a blueprint for failure. The strategic power of a PDS is rooted in its specificity. It must be tailored to the unique language, regulations, and risks of your industry. A template designed for a mobile game would be dangerously inadequate for a medical device.

The entire focus of your document must shift depending on the nature of the product. When you customize your PDS, it transforms from a bureaucratic checkbox into a practical tool for success. This is what separates a decent PDS from an indispensable one.

SaaS and Software Products

For a Software-as-a-Service (SaaS) product, the PDS must be laser-focused on user experience and the underlying architecture. Physical materials are irrelevant; your world is defined by data flows, security protocols, and user interactions.

Your PDS must go deep in several key areas:

- User Stories and Epics: Instead of listing physical components, you detail user goals. What job is the user trying to accomplish, and how will your features facilitate that?

- API Specifications: Meticulous API documentation is non-negotiable for scalability and third-party integrations.

- Data Privacy & Compliance: You must be crystal clear about how you will handle user data to comply with regulations like GDPR or CCPA. With 47% of companies citing data privacy as a major operational concern, this section cannot be an afterthought.

Nailing these sections ensures your development team understands not only what to build but also the critical technical and legal guardrails within which they must operate.

Consumer Electronics

When dealing with hardware, the PDS becomes a far more tangible document. The focus shifts to the physical product and its journey from design to manufacturing. While user experience is still vital, the technical specs become intensely concrete.

I have seen multi-million dollar projects derailed by a single ambiguous material specification. A PDS for electronics must be so precise that a manufacturing partner on another continent can execute it perfectly without a single clarifying question.

Your template must include ironclad sections covering:

- Bill of Materials (BOM): A complete inventory of every single resistor, screw, and casing component.

- Manufacturing Tolerances: The exact measurements and acceptable deviations. A 0.1mm difference can be the line between a perfect fit and a costly production halt.

- Supply Chain Logistics: Where are components sourced? Who are the suppliers? What are their lead times and potential risks?

Medical Devices and Regulated Hardware

In heavily regulated sectors like med-tech, the PDS is more than a design guide; it is a critical legal and compliance artifact. The stakes are immense, and your PDS must reflect this reality. Often, your primary audience isn’t just your internal team—it’s a regulatory body like the FDA.

For these products, your PDS absolutely must include:

- Regulatory Compliance: Map out exactly how the product will meet standards like FDA 21 CFR Part 820 or achieve its CE marking.

- Risk Analysis: A formal FMEA (Failure Modes and Effects Analysis) is essential. You must systematically identify every potential failure mode, assess its impact, and document mitigation strategies.

- Biocompatibility and Sterilization: If the device has patient contact, you must specify the exact materials and sterilization processes that guarantee safety.

Cutting corners on these sections in your product design specification template doesn’t just risk project delays; it can lead to outright regulatory rejection, costing months or even years of progress.

Turning Your PDS Into a Living, Breathing Document

A brilliant product design specification template is worthless if it just gathers digital dust. Its value is realized when the team actively uses it, transforming a static file into the project’s central nervous system. The objective is to make the PDS a daily guide, not just another piece of paperwork to check off and forget.

This cultural shift begins at project kickoff. Don’t just present the PDS as a list of rules. Frame it as the team’s collective agreement on what you’re building and, crucially, why.

Ownership is key. While the product manager typically steers the document, different experts should own their respective sections. The lead engineer owns the technical specifications. The design lead owns the UX and UI requirements. This distributed ownership fosters both accountability and buy-in.

Weaving the PDS into Your Daily Workflow

True alignment isn’t achieved in a single meeting; it’s built through daily habits. The only way to make the PDS effective is to integrate it directly into the tools and routines your team already uses.

- Connect it to your task manager: When you create a story in Jira or a task in Asana , link directly to the relevant section of the PDS. This gives engineers instant context—the “why” behind the “what”—without them having to hunt for it.

- Maintain rigorous version control: This is non-negotiable. A clear change log at the top of the document is a lifesaver. It should track who changed what, when, and why. This simple practice prevents a world of confusion and ensures everyone is working from the same plan.

This isn’t just theory. Research shows that teams with a living, integrated design specification report a 40% decrease in costly post-launch fixes, demonstrating a direct impact on the bottom line. If you’re curious, you can read the full research about these findings to see the data for yourself.

When you treat the PDS as a living hub for the project, you elevate it from a simple document to a powerful tool for clarity and collaboration. That active, daily engagement is what makes your product design specification template a true asset for building successful products.

Common PDS Mistakes That Derail Projects

Even with the best product design specification template, projects can be derailed by a few common, avoidable mistakes. The single biggest culprit is vague requirements. Phrases like “fast performance” or “user-friendly interface” are meaningless without metrics. Leaving requirements open to interpretation is an invitation for mismatched features and expensive rework.

However, the opposite is equally damaging. A PDS that is overly prescriptive can stifle innovation. Your goal is to define the problem and the constraints, not to dictate the exact technical solution. Give your designers and engineers the space to do what they do best: solve complex problems creatively.

Forgetting Key Stakeholders

This happens with alarming frequency: critical team members are excluded from the PDS creation process. A classic example is failing to involve the Quality Assurance (QA) team early on. If they aren’t consulted, you risk defining acceptance criteria that are untestable, creating a massive bottleneck just before launch.

Another critical error is treating the PDS like a stone tablet. It is not. A PDS must be a living document that evolves as you learn. If it isn’t updated to reflect new information or decisions, your teams will inevitably work from outdated assumptions, and alignment will disintegrate.

How do you avoid these pitfalls? A simple yet powerful practice is to vet every requirement against the SMART criteria. This framework forces clarity and accountability.

- Specific

- Measurable

- Achievable

- Relevant

- Time-bound

Adopting this discipline transforms your PDS from a potential source of confusion into a reliable guide for the entire team. It’s a small change that yields a massive difference in project outcomes.

Got PDS Questions? We’ve Got Answers

Even with a top-tier product design specification template, questions will arise as you apply it to your projects. This is not only normal but essential. Answering these questions is what transforms a PDS from a document you have to create into a tool you want to use.

Let’s address some of the most common points of confusion.

What’s the Real Difference Between a PRD and a PDS?

This is a frequent and important question. The simplest distinction is “what” vs. “how.”

A Product Requirements Document (PRD) focuses on the what. It defines the user’s problem and the business case for solving it. It lists user-centric features and is intended for a broad audience, including marketing, sales, and executive leadership.

The Product Design Specification (PDS), in contrast, drills down into the how. This is the technical blueprint for the engineering and design teams. It details system architecture, material choices, performance metrics, and component-level details. The PDS translates the PRD’s vision into an executable plan.

So, Who’s on the Hook for Writing the PDS?

While the Product Manager typically owns the PDS and is accountable for its completion, its creation is fundamentally a collaborative effort. A great PDS cannot be written in a vacuum.

- Engineering Leads provide the critical technical specifications, architectural decisions, and feasibility analysis.

- Designers contribute the UI/UX details, interaction flows, and visual design requirements.

- QA Specialists define the acceptance criteria and ensure requirements are testable and validated.

The Product Manager acts as the conductor of an orchestra—they don’t play every instrument, but they ensure everyone is working from the same sheet music to produce a cohesive result.

How Often Should We Be Updating This Thing?

A PDS must be a living document, not a “write once, file away” artifact. It must evolve in lockstep with the product itself.

The PDS should be updated any time there is a material change to the product’s scope, core requirements, or technical approach. It must always reflect the current reality of what the team is building.

A good rule of thumb: For major changes (e.g., adding a significant feature), secure formal sign-off from key stakeholders to re-establish alignment. For minor tweaks and clarifications, make the update immediately, but be religious about maintaining a clear version history so everyone can see what changed, when, and why.

Ready to build complex features with AI, guided by perfect context and automated planning? Context Engineering connects directly to your IDE, analyzing your codebase to generate precise requirements and technical plans, acting as your virtual senior PM and architect. Get started in two minutes and build reliable software faster. Learn more about Context Engineering .